Case Study 1: Permian Basin Wireless Pressure Monitoring

- Operator: Mid-sized E&P company

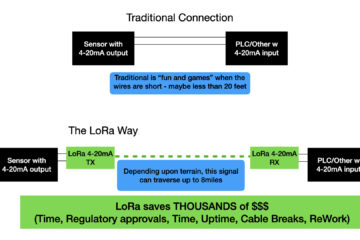

- Challenge: High wiring costs for 50+ wellhead pressure sensors

- Solution: Installed 4-20mA LoRa transmitters (another mfg, but results will be similar)

- Results:

- 85% reduction in installation costs (no trenching/conduit)

- Deployed in 3 days (vs. 3 weeks for wired solution)

- Real-time alerts for pressure drops (reduced downtime by 30%)

Case Study 2: Eagle Ford Shale Tank Level Monitoring

- Operator: Large oilfield services provider

- Challenge: Frequent cable failures in harsh environments

- Solution: Switched to a LoRa based solution

- Results:

- Zero wiring failures in 2+ years

- Battery life exceeded 5 years (no maintenance needed)

- SCADA integration reduced manual checks by 90%

Case Study 3: West Texas Pipeline Leak Detection

- Operator: Pipeline logistics company

- Challenge: Slow response to leaks due to delayed wired sensor data

- Solution: Installed LoRa based flow meters

- Results:

- Leak detection time reduced from 8 hours to 15 minutes

- Saved $250K/year in spill remediation costs

3. How to Get Started

Step 1: Assess Your Current Sensors

- Identify which 4-20mA devices can be replaced with LoRa.

- Prioritize high-maintenance or hard-to-wire locations.

Step 2: Choose a Texas-Based Distributor

- Look for suppliers with:

- Local inventory (avoid 2-4 week lead times)

- On-site support (for troubleshooting)

Step 3: Pilot Test in a Small Section

- Deploy 5-10 LoRa sensors in a single well pad.

- Validate range, battery life, and SCADA integration.

Step 4: Full-Scale Rollout

- Scale across the entire field in phases.

- Train field techs on wireless diagnostics.

Final Thoughts

Texas oilfields are ideal for LoRa wireless adoption due to their vast, remote nature. By working with a local stocking distributor, companies can cut costs, speed up installations, and simplify monitoring—without sacrificing reliability.

0 Comments