Introduction

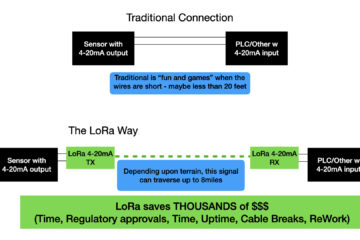

The oil and gas industry relies heavily on accurate, real-time data monitoring to optimize production, ensure safety, and reduce downtime. Traditional 4-20mA current loops have been the backbone of industrial instrumentation for decades, but they come with significant drawbacks—high installation costs, wiring complexity, and maintenance challenges.

By switching to LoRa (Long Range) wireless replacements for 4-20mA loops, oilfield operators can achieve lower costs, faster installations, and simplified monitoring operations. Partnering with a Texas-based stocking distributorfor these solutions provides additional advantages, including local inventory availability, reduced lead times, and expert technical support tailored to the oilfield environment.

1. Cost Savings with LoRa Wireless Replacements

Elimination of Wiring Costs

Traditional 4-20mA loops require extensive cabling, conduit, and labor for installation. In remote oilfields, wiring costs can skyrocket due to:

- Long cable runs (hundreds or thousands of feet)

- Conduit and trenching expenses

- Labor-intensive terminations and troubleshooting

LoRa wireless transmitters eliminate the need for wiring, reducing material and labor costs by up to 70%.

Lower Maintenance Costs

- No corrosion or wire degradation (common in harsh oilfield conditions)

- Fewer points of failure (no broken wires, loose connections, or ground loops)

- Remote diagnostics (reduces the need for field technicians to physically inspect wiring)

Scalability Without Additional Infrastructure

Adding new sensors to a wired 4-20mA system often requires additional I/O cards, wiring, and control panel modifications. LoRa networks allow plug-and-play expansion—simply deploy a new wireless transmitter and connect it to the existing gateway.

2. Faster Installations & Reduced Downtime

Rapid Deployment in Remote Locations

- No trenching or conduit installation means sensors can be deployed in hours instead of days.

- Battery-powered LoRa devices (5-10 year lifespan) eliminate the need for power wiring.

- Pre-configured wireless networks allow for immediate data transmission.

Minimized Production Disruptions

Retrofitting wired systems often requires shutting down sections of the oilfield for installation. Wireless LoRa sensors can be installed without interrupting operations, keeping production flowing.

Local Stocking Distributor = Faster Access

A Texas-based stocking distributor ensures:

- Same-day or next-day shipping (no waiting for cross-country deliveries)

- Immediate access to replacement parts (critical for minimizing downtime)

- On-site technical support (for quick troubleshooting and optimization)

3. Simplified Oilfield Data Monitoring

Centralized, Real-Time Data Access

- Cloud-based dashboards provide real-time visibility of pressure, temperature, flow, and other critical parameters.

- Alerts and notifications for abnormal conditions (reducing response times to leaks or equipment failures).

Reduced Complexity in SCADA Integration

- LoRa gateways seamlessly integrate with existing SCADA, PLC, or DCS systems.

- Modbus RTU/TCP or MQTT protocols ensure compatibility with most oilfield control systems.

Enhanced Reliability in Harsh Environments

- LoRa’s long-range (10+ miles in open areas) ensures connectivity across large oilfields.

- Industrial-grade enclosures (IP67/NEMA 4X) protect against dust, moisture, and extreme temperatures.

Why a Texas Stocking Distributor Makes a Difference

1. Local Inventory = Faster Deployment

- No waiting for shipments from out-of-state suppliers.

- Emergency replacements available immediately.

2. Reduced Logistics Costs

- Lower shipping fees compared to suppliers outside Texas.

- On-site support for large-scale deployments.

Conclusion

Replacing traditional 4-20mA current loops with LoRa wireless transmitters offers oilfield operators significant cost savings, faster installations, and simplified data monitoring. Partnering with a Texas-based stocking distributorensures quick access to equipment, local expertise, and reduced downtime, making it the smartest choice for modernizing oilfield instrumentation.

By leveraging LoRa’s long-range, low-power advantages and the convenience of a local supplier, oil and gas companies can streamline operations, cut costs, and improve reliability—keeping their fields running efficiently in today’s competitive market.

Next Steps

- Contact BearMar for a consultation on LoRa solutions.

- Request a demo to see real-world performance in oilfield conditions.

- Plan a phased rollout to minimize disruption while upgrading your monitoring infrastructure.

With the right wireless strategy and a reliable local supplier, your oilfield operations can achieve greater efficiency at a fraction of the cost of traditional wired systems.

0 Comments