Introduction

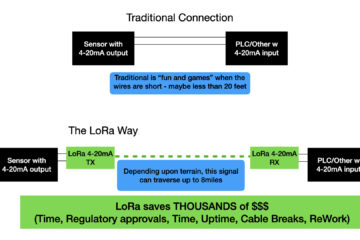

In industrial settings like oilfields, reliable communication is non-negotiable. Traditional wireless technologies such as 2.4GHz WiFi and non-LoRa 900MHz radios often fall short in harsh environments where interference, range, and power constraints are critical factors. LoRa (Long Range) radio technology stands out as the superior choice for industrial applications—especially for monitoring critical parameters like pressure via 4-20mA sensors. This article explores why LoRa outperforms both 2.4GHz WiFi and standard 900MHz radios in terms of reliability, range, power efficiency, and message delivery assurance.

1. Reliability in Harsh Industrial Environments

1.1 LoRa vs. 2.4GHz WiFi

2.4GHz WiFi is widely used but suffers from severe limitations in industrial environments:

- Interference: The 2.4GHz band is crowded with consumer devices (WiFi routers, Bluetooth, microwaves), leading to signal degradation.

- Limited Penetration: High-frequency signals struggle to penetrate dense structures, metal barriers, and underground installations common in oilfields.

- Short Range: WiFi typically maxes out at 100-150 meters in open spaces—far too limited for sprawling oilfield operations.

LoRa’s Advantages:

- Operates in sub-GHz bands (e.g., 868MHz, 915MHz), which penetrate obstacles better.

- Uses Chirp Spread Spectrum (CSS) modulation, making it highly resistant to interference.

- Delivers kilometer-scale range (up to 15+ km in open areas, 3-5 km in dense industrial sites).

- LoRa has 100s of millions of deployed radios making it one of the most battle tested and hardened IoT protocols and radio in the world.

1.2 LoRa vs. Non-LoRa 900MHz Radios

Standard 900MHz radios (e.g., FSK-based) offer better range than WiFi but lack LoRa’s robustness:

- Lower Sensitivity: Non-LoRa 900MHz radios have poorer receiver sensitivity, meaning weaker signals are lost.

- No Adaptive Data Rate (ADR): LoRa dynamically adjusts data rates to optimize range and battery life—standard 900MHz radios cannot.

- No Built-in Error Correction: LoRa’s forward error correction (FEC) ensures message integrity even in noisy environments.

2. Assured Message Delivery for Critical Monitoring

In oilfield operations, dropped sensor readings can lead to catastrophic failures. LoRa ensures near-guaranteed message delivery through:

2.1 Acknowledgment-Based Communication

- LoRaWAN (LoRa’s network protocol) supports confirmed uplinks, where the gateway acknowledges receipt.

- If a message fails, the sensor automatically retransmits, ensuring data integrity.

2.2 Superior Link Budget (Up to 157 dB)

- LoRa’s high link budget means it can maintain connections at extremely low signal levels.

- Standard 900MHz radios typically max out at 120-130 dB, making them unreliable in deep wells or remote pump stations.

2.3 Low Latency for Time-Sensitive Alerts

- While LoRa is not designed for real-time streaming, its low latency (~1-2 seconds) is sufficient for 4-20mA pressure sensor alerts.

- WiFi and non-LoRa 900MHz radios may experience multi-second delays due to congestion or retries.

3. Power Efficiency for Long-Term Deployments

Oilfield sensors often run on batteries or solar power, making energy efficiency crucial.

3.1 LoRa’s Ultra-Low Power Consumption

- LoRa devices can operate for 5-10 years on a single battery.

- WiFi and standard 900MHz radios drain power quickly due to high transmit power and frequent retries.

3.2 Duty Cycle Optimization

- LoRaWAN’s duty cycling ensures sensors only transmit when necessary, reducing energy waste.

- WiFi requires constant polling, and non-LoRa 900MHz radios lack smart scheduling.

4. Scalability for Large-Scale Industrial Networks

Oilfields require hundreds (or thousands) of sensors working in unison.

4.1 LoRa’s Star-of-Stars Architecture

- A single LoRa gateway can handle millions of messages per day from thousands of devices.

- WiFi networks collapse under high device density, and non-LoRa 900MHz radios lack efficient multi-node management.

4.2 Frequency Agility & Adaptive Data Rates

- LoRa shifts frequencies to avoid interference, while WiFi and standard 900MHz radios get stuck on congested channels.

5. Real-World Oilfield Applications

5.1 Pressure Monitoring (4-20mA Sensors)

- LoRa ensures continuous, interference-free readings from wellheads, pipelines, and storage tanks.

- WiFi and non-LoRa 900MHz radios risk data gaps due to signal loss.

5.2 Remote Pump Control & Leak Detection

- LoRa’s long range covers remote well pads without additional repeaters.

- Non-LoRa radios require expensive mesh networks to achieve similar coverage.

Conclusion: Why LoRa is the Best Choice for Oilfield Monitoring

| Feature | LoRa | 2.4GHz WiFi | Non-LoRa 900MHz |

|---|---|---|---|

| Range | 3-15 km | 100-150m | 1-3 km |

| Interference Resistance | Excellent | Poor | Moderate |

| Power Efficiency | 5-10 years battery | Days/Weeks | Months |

| Message Assurance | Confirmed uplinks, FEC | Unreliable | No FEC |

| Scalability | Millions of nodes | Limited by AP capacity | Limited by protocol |

For oilfield pressure monitoring, leak detection, and industrial IoT, LoRa is the only technology that guarantees:

✅ Reliable long-range communication

✅ Assured message delivery

✅ Ultra-low power consumption

✅ Scalability for massive deployments

Final Recommendation

If your oilfield operations depend on 4-20mA sensor networks, switch to LoRa today—WiFi and non-LoRa 900MHz radios simply cannot compete in reliability, range, or efficiency.

0 Comments